Automated Electric bells <Bello>:

Apart from getting the bells and tuning them, this is the easiest problem

to solve. After all, we designed our

'Bellenorgel' already back in 1972... Other than what the score publisher

states (7 different sized bells required) the score prescribes pitches,

notated in the treble staff, and more than 7 bells. Occuring pitches in

the score are: 69, 73,76, 77,78,79,80, 81, 82, 83. This makes 10 bells,

not seven! For the construction of this automaton we generalized the concept

such that we could offer a more continuous range of pitches. Finding suitable

industrial electric bells was not a trivial matter. Moreover, the mechanism

of the bells we got from Infrabel (Funke and Friedland) have a mechanism

using a spring such that the actual hitting of the bell happens at the

release of the electric pulse driving it. This has quite some implications

for the firmware to drive these mechanisms.  Obviously if the pulse lenghts get longer than 10ms, there would be a

noticable latency. The tuning of the bells is possible using a regular

column drill and a clamped file. The ideal tool for doing this is a vertical

lathe, but not too many people do have such equipment available... The

rules are clarified in this little drawing:

Obviously if the pulse lenghts get longer than 10ms, there would be a

noticable latency. The tuning of the bells is possible using a regular

column drill and a clamped file. The ideal tool for doing this is a vertical

lathe, but not too many people do have such equipment available... The

rules are clarified in this little drawing:  The range for tuning is pretty limited. Lowering the pitch can be done

up to a semitone. If you go lower, the sound volume will suffer as the

material gets too thin. Raising the pitch can be done up to a minor third.

Welding on the rim of shell bells made of steel or stainless steel never

gives good results. The bell looses all resonance because of the unavoidable

deformation of the shape.

The range for tuning is pretty limited. Lowering the pitch can be done

up to a semitone. If you go lower, the sound volume will suffer as the

material gets too thin. Raising the pitch can be done up to a minor third.

Welding on the rim of shell bells made of steel or stainless steel never

gives good results. The bell looses all resonance because of the unavoidable

deformation of the shape.

The huh board we designed looks like:  The PCB's for the pulse boards - each board serves 12 bells - looks like:

The PCB's for the pulse boards - each board serves 12 bells - looks like:

The power supply, providing a range of different voltages as required

for the different bell mechanisms is of an utmost simplicity:  As

a continuous current is never drawn in this machine, it's enough to provide

large enough capacitors.

As

a continuous current is never drawn in this machine, it's enough to provide

large enough capacitors.

The note mapping for <Bello> is given under 'midi implementation'

further below. The notes indicated as missing may be added at a later

stage, when we can find suitable dome bells. For the notes 62, 63 and

66 we used U-shaped pieces of steel tuned to the right pitches. These

bells have different sonic qualities as they are not real dome bells.

Users of our robot orchestra that are really in need of the missing lower

bells, can use the bells on our <Llor> and/or <Belly> robots.

For an alternative F# (note 66) the <Harma>

robot includes this one as well. Note that this robot uses mostly bells

from very different origins and of very different composition, hence their

sonic qualities are very different. It was not our intention to create

a homogenous instrument in terms of sound color.

The mapping of midi key pressure commands on note repetition frequency

is given in the following table:

| MIDI key pressure value |

Frequency (Hz) |

Period duration in 24µs units |

|

1

|

.999992000063999

|

41667

|

|

2

|

1.06659840436879

|

39065

|

|

3

|

1.1015350993144

|

37826

|

|

4

|

1.13762536631537

|

36626

|

|

5

|

1.17490036844876

|

35464

|

|

6

|

1.21339196443305

|

34339

|

|

7

|

1.25317052141919

|

33249

|

|

8

|

1.29419682145261

|

32195

|

|

9

|

1.3366267817235

|

31173

|

|

10

|

1.38042229878964

|

30184

|

|

11

|

1.42562242675152

|

29227

|

|

12

|

1.47237240420745

|

28299

|

|

13

|

1.52057027467581

|

27402

|

|

14

|

1.57043067490829

|

26532

|

|

15

|

1.62183903571938

|

25691

|

|

16

|

1.67497454038699

|

24876

|

|

17

|

1.72991225885023

|

24086

|

|

18

|

1.78658205414058

|

23322

|

|

19

|

1.84512738759484

|

22582

|

|

20

|

1.90554590078966

|

21866

|

|

21

|

1.96800806096102

|

21172

|

|

22

|

2.03242118270653

|

20501

|

|

23

|

2.09907640638119

|

19850

|

|

24

|

2.16788067984738

|

19220

|

|

25

|

2.23881933623484

|

18611

|

|

26

|

2.31224565297817

|

18020

|

|

27

|

2.38791143714062

|

17449

|

|

28

|

2.4662128834961

|

16895

|

|

29

|

2.54701795138252

|

16359

|

|

30

|

2.63047138047138

|

15840

|

|

31

|

2.71656452384057

|

15338

|

|

32

|

2.80564720669764

|

14851

|

|

33

|

2.89754288363468

|

14380

|

|

34

|

2.99243512400651

|

13924

|

|

35

|

3.09054047371804

|

13482

|

|

36

|

3.19186966957765

|

13054

|

|

37

|

3.2964135021097

|

12640

|

|

38

|

3.40441757224174

|

12239

|

|

39

|

3.51587770370995

|

11851

|

|

40

|

3.63108206245461

|

11475

|

|

41

|

3.750037500375

|

11111

|

|

42

|

3.87308669517258

|

10758

|

|

43

|

3.99987200409587

|

10417

|

|

44

|

4.13113887236433

|

10086

|

|

45

|

4.26650283295788

|

9766

|

|

46

|

4.40590744069648

|

9457

|

|

47

|

4.55025299406647

|

9157

|

|

48

|

4.69960147379502

|

8866

|

|

49

|

4.8534265191225

|

8585

|

|

50

|

5.01222984081158

|

8313

|

|

51

|

5.17662649604506

|

8049

|

|

52

|

5.34667864322683

|

7793

|

|

53

|

5.52168919515858

|

7546

|

|

54

|

5.70229460334839

|

7307

|

|

55

|

5.88928150765606

|

7075

|

|

56

|

6.08183720138179

|

6851

|

|

57

|

6.28172269963315

|

6633

|

|

58

|

6.48710363796772

|

6423

|

|

59

|

6.69989816154794

|

6219

|

|

60

|

6.91907450459426

|

6022

|

|

61

|

7.14571542902875

|

5831

|

|

62

|

7.37985594521195

|

5646

|

|

63

|

7.62148649472593

|

5467

|

|

64

|

7.87203224384407

|

5293

|

|

65

|

8.13008130081301

|

5125

|

|

66

|

8.39545973537511

|

4963

|

|

67

|

8.67152271938952

|

4805

|

|

68

|

8.95479618883874

|

4653

|

|

69

|

9.24898261191269

|

4505

|

|

70

|

9.55219318355494

|

4362

|

|

71

|

9.86426767676768

|

4224

|

|

72

|

10.1874490627547

|

4090

|

|

73

|

10.5218855218855

|

3960

|

|

74

|

10.867675186924

|

3834

|

|

75

|

11.2218331986713

|

3713

|

|

76

|

11.5901715345387

|

3595

|

|

77

|

11.969740496026

|

3481

|

|

78

|

12.3603282903194

|

3371

|

|

79

|

12.765522875817

|

3264

|

|

80

|

13.1856540084388

|

3160

|

|

81

|

13.6165577342048

|

3060

|

|

82

|

14.0623242209472

|

2963

|

|

83

|

14.523062623446

|

2869

|

|

84

|

14.9988000959923

|

2778

|

|

85

|

15.4894671623296

|

2690

|

|

86

|

16.0010240655402

|

2604

|

|

87

|

16.5212794078773

|

2522

|

|

88

|

17.0625170625171

|

2442

|

|

89

|

17.6254935138184

|

2364

|

|

90

|

18.202999854376

|

2289

|

|

91

|

18.7941662907833

|

2217

|

|

92

|

19.4159676918298

|

2146

|

|

93

|

20.0513314084055

|

2078

|

|

94

|

20.7090788601723

|

2012

|

|

95

|

21.3894592744695

|

1948

|

|

96

|

22.0809044338456

|

1887

|

|

97

|

22.8060572888159

|

1827

|

|

98

|

23.5537968720558

|

1769

|

|

99

|

24.3237984043588

|

1713

|

|

100

|

25.1306795335746

|

1658

|

|

101

|

25.9443752594438

|

1606

|

|

102

|

26.7952840300107

|

1555

|

|

103

|

27.6854928017719

|

1505

|

|

104

|

28.5779606767261

|

1458

|

|

105

|

29.5298842428538

|

1411

|

|

106

|

30.480370641307

|

1367

|

|

107

|

31.4940791131267

|

1323

|

|

108

|

32.5266718709342

|

1281

|

|

109

|

33.5750738651625

|

1241

|

|

110

|

34.6933111296142

|

1201

|

|

111

|

35.8268844941244

|

1163

|

|

112

|

37.00414446418

|

1126

|

|

113

|

38.1912618392912

|

1091

|

|

114

|

39.4570707070707

|

1056

|

|

115

|

40.7697325505545

|

1022

|

|

116

|

42.0875420875421

|

990

|

|

117

|

43.4480361487661

|

959

|

|

118

|

44.8994252873563

|

928

|

|

119

|

46.347793845013

|

899

|

|

120

|

47.8927203065134

|

870

|

|

121

|

49.4266508501384

|

843

|

|

122

|

51.062091503268

|

816

|

|

123

|

52.7426160337553

|

790

|

|

124

|

54.4662309368192

|

765

|

|

125

|

56.2303193882141

|

741

|

|

126

|

58.1125058112506

|

717

|

|

127

|

60.0384245917387

|

694

|

Note that it is very important to decrease the velocity values as the

note repeat frequencies are increased. Not only will the bells not sound

properly, but moreover, there is a high risk of burning out the coils.

The safe maximum value for keypressure is 106. This value guarantees the

duty cycle to be lower than 50%. However, users should not consider this

to be the optimum value. At high repetition rates, the lowest possible

velocity values generally sound best. The highest possible repetition

rate corresponds to that of a 60 Hz American AC driven alarmbell. European

AC driven alarmbells sound at 50Hz. Ordinary AC/DC bells using an interruptor

mechanism have much lower repetition rates. Modern bells have faster repetition

rates (due to their lighter construction) than antique ones. For quite

a few 19th century electric bells, we measured repetition rates as low

as 4 Hz under normal operating conditions.

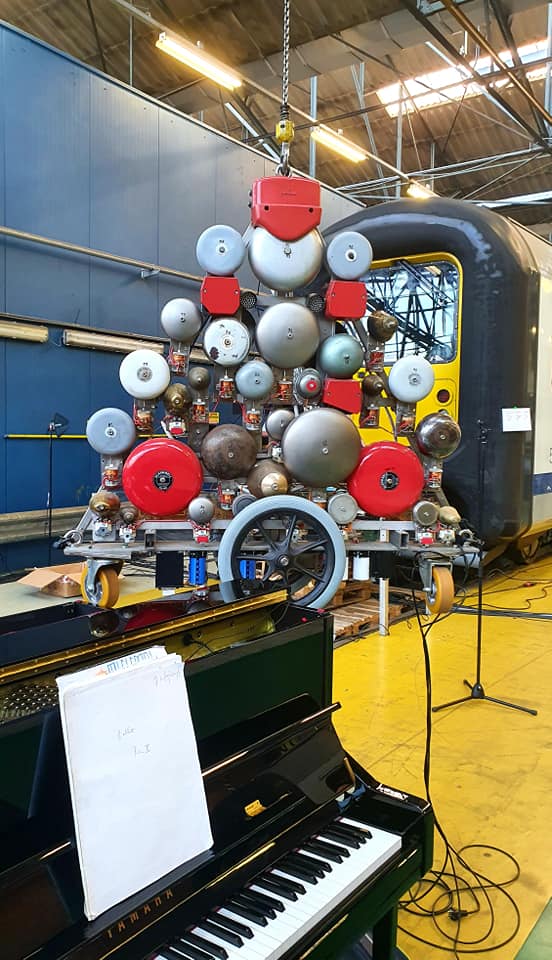

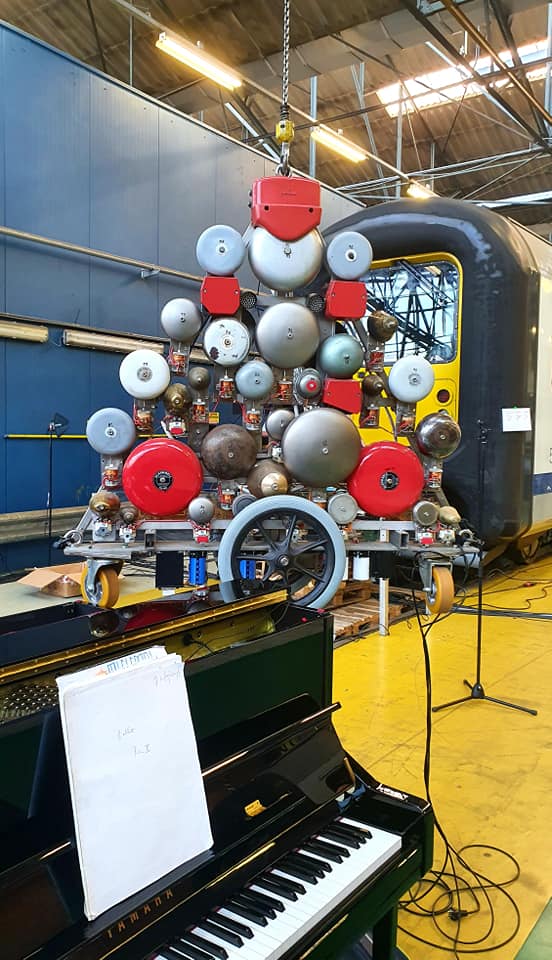

Here is a picture of the <Bello> robot, ready to be fully suspended

for a performance of Antheil's Ballet Mecanique in the village of Mechelen,

march 2022:

Midi implementation:

- Channel 13

- Note-on commands: the velocity byte steers the force wherewith the

bells are struck:

- Note-Off or Note-on with velo = 0 turns the bell off

- Key-pressure commands are used to set the repetition speed of the

bell strokes. These repetition speeds (cfr. table above) are individually

programmable for each bell. When set to zero, the bells will not repeat

but produce a single stroke. Note that the keypressure commands are

sticky and are memorised for each note.

- The two red lights in front are mapped on notes 126 and 127, the velocity

byte steers the flashing speed.

- The red light underneath the front is mapped on note 119, the velocity

byte steers the brightness.

- Controller 30: This controller can be used to set all the repeat frequencies

to one and the same value for all bells. It is a quick way to set the

repetitions rates and an alternative for the key-pressure commands.

However, the time between sending this controller many times should

be kept reasonably long, as it requires reprogramming of all lookup

tables in the firmware. It is advised to send this controller at a time

when no bells are sounding. If this is not done, glitches and irregular

performance may become audible. Note repetition rate is controlled by

the parameter value. To switch repetition off, a zero value should be

send.

- Controller 66: enables (>0) or disables (=0) bell operations. CC66

= 0 resets all keypressure values to zero.

- Controller 123: all notes off, stops all bells, preserving the key

pressure values and thus the repetition rates..

Note: if the robot is left switched

on, it will automatically reset all repeat values and switch all notes

off after 7 hours of operation.

Music

composed for <Bello>:

Godfried-Willem Raes

'Namuda Study #53: Bello', premiered April 22nd 2015 by Dominica Eyckmans

and the author. Performed again with Emilie De Vlam 09.2017.

George Antheil 'Ballet Mechanique', premiered with <Bello> and

the propellers, May 3th 2015, Flanders Festival

Zwevegem / Kortrijk.

Godfried-Willem Raes

'Onmogelijk', a namuda dance production (21,22,23.07.2015) [also uses

the propellers]

Kristof Lauwers 'Study #24', for <Bello>

The range for tuning is pretty limited. Lowering the pitch can be done

up to a semitone. If you go lower, the sound volume will suffer as the

material gets too thin. Raising the pitch can be done up to a minor third.

Welding on the rim of shell bells made of steel or stainless steel never

gives good results. The bell looses all resonance because of the unavoidable

deformation of the shape.

The range for tuning is pretty limited. Lowering the pitch can be done

up to a semitone. If you go lower, the sound volume will suffer as the

material gets too thin. Raising the pitch can be done up to a minor third.

Welding on the rim of shell bells made of steel or stainless steel never

gives good results. The bell looses all resonance because of the unavoidable

deformation of the shape. The PCB's for the pulse boards - each board serves 12 bells - looks like:

The PCB's for the pulse boards - each board serves 12 bells - looks like:

As

a continuous current is never drawn in this machine, it's enough to provide

large enough capacitors.

As

a continuous current is never drawn in this machine, it's enough to provide

large enough capacitors.

The 500 VA transformer as well as the high voltage electrolytics came

in from Farnell. Thus we can go on with the construction of the power

supply. This is the circuit drawing:

The 500 VA transformer as well as the high voltage electrolytics came

in from Farnell. Thus we can go on with the construction of the power

supply. This is the circuit drawing:

When

the 12V supply voltage is off, both relays will be off. It looks like

a good solution for the braking circuit on the propeller motors.

When

the 12V supply voltage is off, both relays will be off. It looks like

a good solution for the braking circuit on the propeller motors. Start

construction of the bottom plate (10 mm thick stainless steel plate 1310

mm long, 100 mm wide): drilling of mounting holes for the side wheels,

construction of an axle holder for the front and back wheels, drilling

of mounting holes for the power supply transformers.

Start

construction of the bottom plate (10 mm thick stainless steel plate 1310

mm long, 100 mm wide): drilling of mounting holes for the side wheels,

construction of an axle holder for the front and back wheels, drilling

of mounting holes for the power supply transformers. And this is what the PCB looks like:

And this is what the PCB looks like:  Hopefully we have the time to etch and solder this before the Antheil

piece goes into production... this weekend. In fact it would be a good

idea to provide some place on the PCB for a simple SMPS 12V power supply,

as this would allow us to mount two red LED spotlights on this propeller

as well...

Hopefully we have the time to etch and solder this before the Antheil

piece goes into production... this weekend. In fact it would be a good

idea to provide some place on the PCB for a simple SMPS 12V power supply,

as this would allow us to mount two red LED spotlights on this propeller

as well... Firmware for the AXO board written by Lara Van Wynsberghe. The connections

for the Axoloti board look like this:

Firmware for the AXO board written by Lara Van Wynsberghe. The connections

for the Axoloti board look like this: