<Balsi>: Large motor

driven siren

The instructions in the score render it impossible to

use a standard crank driven siren, as it is detrimental to the gears in

these devices to be started and stopped fast. So an electrically driven

mechanical siren with safe braking possibilities or fast sound control

has to be designed. The score is very unclear as to the pitches the sirens

are supposed to sound. In the score they appear notated as percussion

instruments. We made already a few siren driven robots: <Sire>

, a robot using 24 small sirens as well as the large siren integrated

in <Springers>.

The documentation for <Balsi> is

on a separate webpage. Click here.

Player Pianos:

The original score requires 16 player piano's, although there are only

four autonomous tracks. The reason behind this, is that on traditional

piano rolls, it is impossible to have that amount of notes as the paper

would fall into pieces. Obviously electrically driven automated pianos

do not have this restriction making performances using just 4 player pianos

perfectly possible. All performances so far if using player pianos (and

not sample-based midi keyboards with their uggly sound...) at all, suffered

from the problems associated with commercially available midi controlled

pianos: latency (500ms), lack of polyphony, weak dynamic possibilities.

This is the case for the Yamaha Disklavier, the Q&R vorsetzers etc...

The player pianos as we designed and build do not have any of these problems.

Detailed descriptions and comments on our Player

Piano's can be found on this website. The only problem is that at

the time of this writing (2015) we made only two copies. So either we

have to make two more vorsetzers, or rearrange the score to get it played

on the two pianos we already have.

Musicians parts:

The score calls furthermore for three xylophones, two grand pianos, a

tamtam, four bass drums. It is perfectly possible to also confine these

parts to real musical robots. Our <Xy>

robot can take care of the xylophone parts. Automating the bass drums

and a tamtam would be pretty straightforward...

Midi Implementation for all components of <Balmec>

The Balmec project was conceived to work like all other musical robots

we have built. Hence it makes use of one unique midi-channel and all components

of the project are mapped on midi notes and controllers.

Midi channel: 13 (counting from 0) for all modules.

Note On/Off mapping:

Note 24: Siren. The maximum speed is controlled by controller #24. Note-On

commands let the siren speak freely, Note-Off commands mute the siren.

To stop the siren motor, controller 24 must be set to zero.

Note 36: propeller 3 (large metal propeller). The speed of rotation is

controlled by the velocity byte

Note 38: propeller 2 (large wood propeller). The speed of rotation is

controlled by the velocity byte

Note 40: propeller 1 (small propeller). The speed of rotation is controlled

by the velocity byte

Notes 51 - 93: Electric bells on <Bello>. The velocity byte

steers the loudness (the force of the stroke) and repetition rate can

be controlled with the key pressure command. The repetition speed set

with the key pressure command is 'sticky', so users do not have to send

it again for every note. The key pressure command can also be sent when

no notes are playing. If the repetition rates are set high, low velocity

values ought to be used.

Note 119: switch on/off the red LED bottom lights on <Bello>. The

velocity steers the brightness of the light.

Notes 120 and 121 switch on/off the red LED spotlights on propeller 1.

The velocity steers the speed of the flashing. Keypressure can be used

to further modulate the flashing speed.

Notes 122 and 123 switch on/off the red LED spotlights on propeller 2.

The velocity steers the speed of the flashing. Keypressure can be used

to further modulate the flashing speed.

Notes 124 and 125 switch on/off the red LED spotlights on propeller 3.

The velocity steers the speed of the flashing. Keypressure can be used

to further modulate the flashing speed.

Notes 126 and 127 switch on/off the red LED spotlights on <Bello>.

The velocity steers the speed of the flashing. Keypressure can be used

to further modulate the flashing speed.

Controller 66: Switches off all components when the data byte is zero.

If a non-zero value is sent, the components are powered on. Controller

66 with value zero also resets all controllers to their default startup

values.It also resets the note-repetion rates on <Bello>.

Controller 123: All notes off, without affecting any controllers nor

key-pressure settings.

Prof.dr.Godfried-Willem Raes

Collaborators on this project:

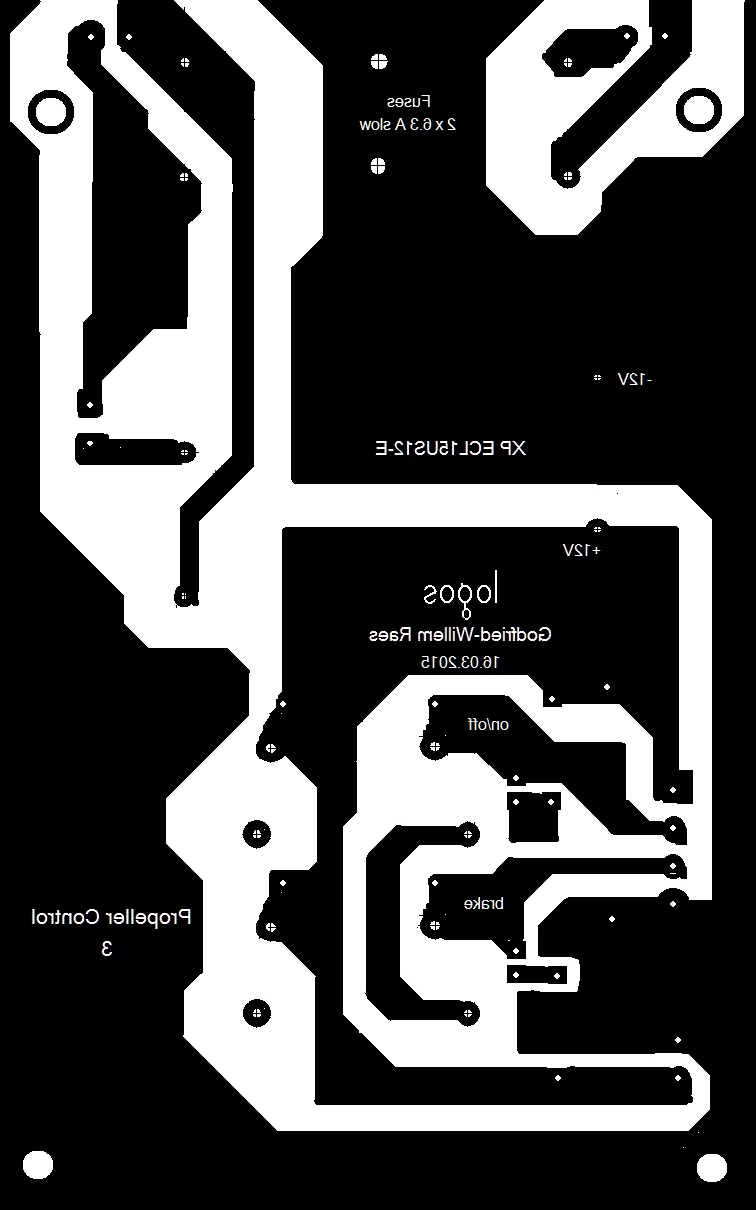

And, this

the PCB for the above circuit.

And, this

the PCB for the above circuit. As we did not find enough space on the board to accomodate a 2.2mF / 450V

electrolytic as originally foreseen in the schematic, we mounted a 470uF/400V

type. If a larger value is required it will have to be added off-board.

The motor brake relay as well as the braking resistor (or light bulb)

should be mounted on the motor itself. As parts of the PCB are directly

coupled to the mains voltage a word of warning may not be misplaced here:

this board does carry high voltages! Do not touch. There is galvanic isolation

between input and output, so using the circuit involves no danger. The

steel structure itself is properly grounded.There are two automatic fuses

on the machine making it possible to cut all power, however these fuses

should not be used as a switch taking into account that being in such

close proximity to the propeller entails a danger in its own, For safety

reasons we advise users to use a switch in the power wire at least 5 meters

away from the engine.

As we did not find enough space on the board to accomodate a 2.2mF / 450V

electrolytic as originally foreseen in the schematic, we mounted a 470uF/400V

type. If a larger value is required it will have to be added off-board.

The motor brake relay as well as the braking resistor (or light bulb)

should be mounted on the motor itself. As parts of the PCB are directly

coupled to the mains voltage a word of warning may not be misplaced here:

this board does carry high voltages! Do not touch. There is galvanic isolation

between input and output, so using the circuit involves no danger. The

steel structure itself is properly grounded.There are two automatic fuses

on the machine making it possible to cut all power, however these fuses

should not be used as a switch taking into account that being in such

close proximity to the propeller entails a danger in its own, For safety

reasons we advise users to use a switch in the power wire at least 5 meters

away from the engine.

The power

relays, the fuse holder and the SMPS 12V power supply found a place on

another printed circuit board:

The power

relays, the fuse holder and the SMPS 12V power supply found a place on

another printed circuit board:  Making this board made final wiring a lot more transparant than was the

case for propeller 2.

Making this board made final wiring a lot more transparant than was the

case for propeller 2.

The 500 VA transformer as well as the high voltage electrolytics came

in from Farnell. Thus we can go on with the construction of the power

supply. This is the circuit drawing:

The 500 VA transformer as well as the high voltage electrolytics came

in from Farnell. Thus we can go on with the construction of the power

supply. This is the circuit drawing:

When

the 12V supply voltage is off, both relays will be off. It looks like

a good solution for the braking circuit on the propeller motors.

When

the 12V supply voltage is off, both relays will be off. It looks like

a good solution for the braking circuit on the propeller motors. Arc

welding of the tripod for propeller 3. The halogen bulbs (205W) came in

from Conrad as well as a bunch of Weidmueller connectors from Farnell.

Arc

welding of the tripod for propeller 3. The halogen bulbs (205W) came in

from Conrad as well as a bunch of Weidmueller connectors from Farnell. Start

construction of the bottom plate (10 mm thick stainless steel plate 1310

mm long, 100 mm wide): drilling of mounting holes for the side wheels,

construction of an axle holder for the front and back wheels, drilling

of mounting holes for the power supply transformers.

Start

construction of the bottom plate (10 mm thick stainless steel plate 1310

mm long, 100 mm wide): drilling of mounting holes for the side wheels,

construction of an axle holder for the front and back wheels, drilling

of mounting holes for the power supply transformers. And this is what the PCB looks like:

And this is what the PCB looks like:  Hopefully we have the time to etch and solder this before the Antheil

piece goes into production... this weekend. In fact it would be a good

idea to provide some place on the PCB for a simple SMPS 12V power supply,

as this would allow us to mount two red LED spotlights on this propeller

as well...

Hopefully we have the time to etch and solder this before the Antheil

piece goes into production... this weekend. In fact it would be a good

idea to provide some place on the PCB for a simple SMPS 12V power supply,

as this would allow us to mount two red LED spotlights on this propeller

as well...